Over the years, vehicle manufacturers have strived to extend the life-span of their products without compromising their quality. As cars and airplanes are expected to last longer, so are all the components that can be found in them. From cushions to recliners, seat warmers to armrests, these components have to endure years of usage, natural elements, and UV exposure and still be able to function properly.

Over the years, vehicle manufacturers have strived to extend the life-span of their products without compromising their quality. As cars and airplanes are expected to last longer, so are all the components that can be found in them. From cushions to recliners, seat warmers to armrests, these components have to endure years of usage, natural elements, and UV exposure and still be able to function properly.

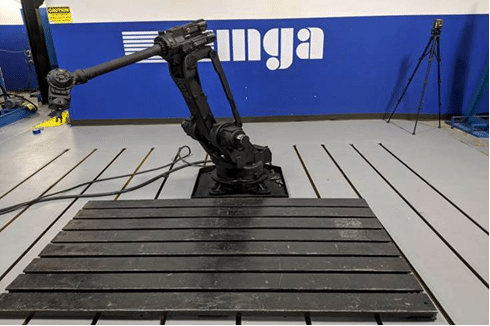

MGA recognizes the importance of product life cycle evaluations, and as our customer testing needs grow, MGA is there to support them. In order to better serve the automobile and aerospace industries, MGA is increasing capabilities in our Texas location to support additional life cycle testing. MGA Texas is currently equipped with two Smart Pneumatic Controllers and one Nachi robot arm.

The Smart Pneumatic Controllers are designed and built by MGA, and with over a decade of experience they are tailored made to serve the aerospace and automotive industry needs. The controllers are capable of operating 8 cylinders concurrently, each reaching up to 200 psi. They are capable of simultaneously performing up to 4 different tests, have a force feedback option, and run continuity checks on electrical harnesses at pre-set cycle counts. The controllers are designed to run 24/7, and are currently set up on a 12ft by 15ft bed-plate in a fully adjustable static test cage. This footprint and adjustable frame allow us to test articles of all sizes and shapes with minimal set-up time.

For more complex motions, such as aircraft stowed tray tables/video monitors deployments and engagements, a Nachi Robot Arm can be used. The arm is servo-controlled and fully programmable, allowing for precise and repeatable movements over the span of thousands of cycles.

With our recent expansions in Texas, MGA will now be able to offer closer lifecycle testing to anyone in the West, Southwest, and Southeast regions, as well as support to other MGA facilities.