Opened in 2012, MGA’s Texas operation in Irving initially focused on state-of-the-art safety testing capabilities for the Aerospace industry. Providing MGA’s customers with superior services has allowed us to become a reliable partner to OEMs and suppliers in that industry. As time went on, our automotive customers in Mexico and South America have experienced substantial growth and as a result needed a partner to keep up with their demand. This has been the driving force for the recent expansion into automotive safety, quality, and durability in Texas. MGA is currently recognized worldwide as one of the leading independent providers of testing services and equipment for the automotive industry, and we are bringing that experience and reputation to Texas.

Opened in 2012, MGA’s Texas operation in Irving initially focused on state-of-the-art safety testing capabilities for the Aerospace industry. Providing MGA’s customers with superior services has allowed us to become a reliable partner to OEMs and suppliers in that industry. As time went on, our automotive customers in Mexico and South America have experienced substantial growth and as a result needed a partner to keep up with their demand. This has been the driving force for the recent expansion into automotive safety, quality, and durability in Texas. MGA is currently recognized worldwide as one of the leading independent providers of testing services and equipment for the automotive industry, and we are bringing that experience and reputation to Texas.

Our Texas’s facility spans 30,000 square feet and has a highly trained, multicultural team that boasts the ability to communicate in four languages, including Spanish. This is the most recent example of our collaborative endeavor in delivering quality and consistent services. With existing capabilities of servo-hydraulic static testing, customized pneumatic static testing, dynamic sled testing, high frequency vibration, and a temperature chamber (reaching between -30°C to 80°C), our recent expansion efforts are geared towards temperature/humidity, lifecycle, and materials testing. We have added the following equipment to support full automotive interior DVP&R:

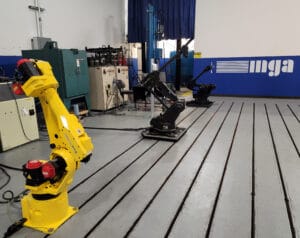

Three robotic arms

Two Nachi and one Fanuc robots are capable of load application (tension and compressions), displacement-controlled motions, and memorizing motion steps for cycling. The purpose of these robots is to support rigidity, and cycle testing in displacement-controlled environments.

Five chambers

Ranging from 3’X 3’ reach-in to 12’X 14’ drive-in, we can now support wider temperature ranges -40°F to 194°F (-40°C to 90°C), larger test articles, and a bigger volume of programs to complement our cycling services. All added chambers have humidity control and possibility for heat lamp addition for higher surface temperature.

One UTM

with a capacity of 1,000 lbs,(2,205 kg) This Universal Testing Machine will allow us to support overall materials testing services, as well as component strength on automotive interior and exteriors.

One power controller & One electric servo controller

The Power controller allows us to send AC & DC signals for power seat and component cycling. The Electric servo controller is a new technology developed by MGA to support rigidity, cycle testing in force-controlled environments.

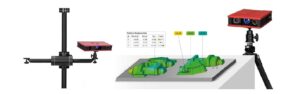

One GOM 3D scanner

This scanner supplies quick and highly accurate deformation overlays as well as fit and finish measurements.

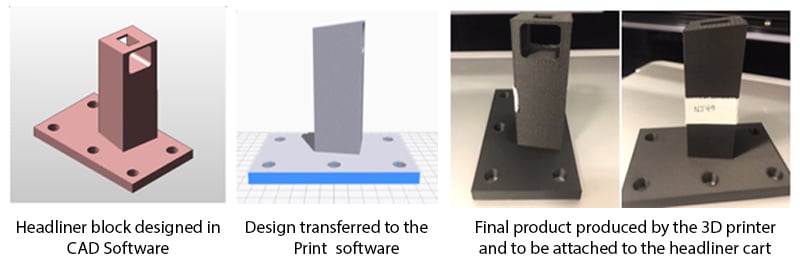

Three 3D printers

Being able to reduce timing and cost on the manufacturing process for supporting fixtures is a great advantage our automotive customers have at MGA. In fact, these savings (both timing and cost) as directly translated to our proposals allowing us to remain competitive and honor our commitments to the industries we serve. The current printing material Onyx prints ready to use right off the print bed and has a heat deflection rating of 145°C. Onyx can be combined with other materials such as carbon fiber, Kevlar, or fiberglass layers to further reinforce it. MGA is also currently experimenting with other materials such as carbon fiber.

MGA maintains a continuous commitment to providing our customers with the best service possible, leading to the growth in capabilities of our Texas facility while not compromising our existing services and customer support.