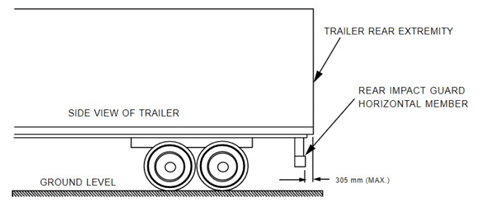

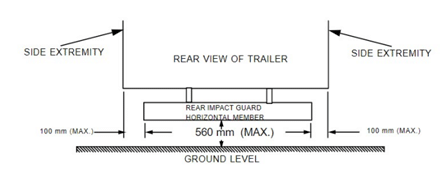

In the past, when passenger vehicles collided with the rear end of trailers or semi-trucks, the results were often catastrophic. The low height of many light vehicles resulted in the car's front end slipping beneath the trailer, often leading to passenger fatalities upon impact. To address this safety concern, the National Highway Traffic Safety Administration (NHTSA) introduced Federal Motor Vehicle Safety Standards (FMVSS) Nos. 223 and 224 in 1996. FMVSS 223 specifies the strength and energy absorption requirements for rear impact guards, and FMVSS 224 mandates new trailers and semitrailers be equipped with a rear guard that meets FMVSS 223 standards. By implementing these rear impact guards, under riding incidents are significantly reduced, and occupants are better protected during collisions with trailers. Recently, FMVSS 223 and 224 received their first major update in decades, prompting MGA to create new testing equipment for evaluating rear underride guards against these heightened standards.

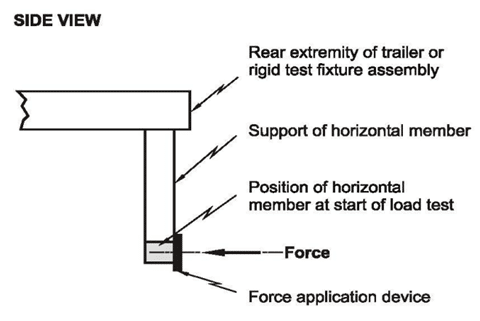

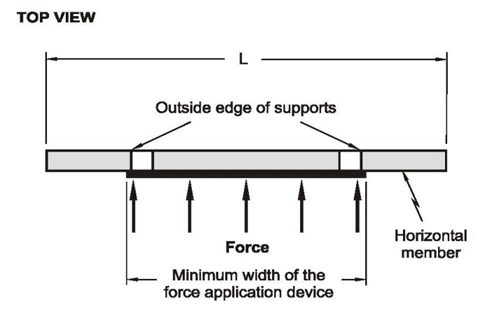

Section 23011 of the recently enacted Bipartisan Infrastructure Law, signed in late 2021, directed the Secretary to upgrade current Federal safety standards for rear underride guards. As of November 2022, FMVSS 223 now requires rear guards manufactured after July 2024 to have sufficient strength and energy absorption capability to protect occupants of passenger cars impacting the rear of trailers at 35-mph. Previously, FMVSS 223 only mandated that rear impact guards be tested to the forces seen in a 30-mph impact, and this 5-mph increase translates to a 36 percent increase in crash energy. Because of these changes, the static strength requirements for rear guards have increased dramatically. They must now withstand a uniform distributed load of 350,000 N while limiting deflection to no more than 125 mm, compared to the previous peak load requirement of 100,000 N at specific points on the guard. As one of the industry leaders in FMVSS 223 testing, MGA Research has designed upgraded test equipment to help clients verify that their rear impact guards meet the new FMVSS 223 requirements.

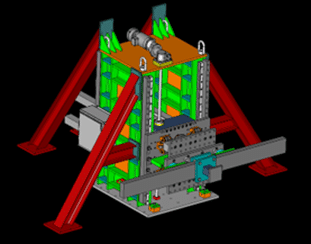

To meet the updated FMVSS 223 specifications, MGA's personnel undertook the task of designing an advanced test system that could deliver optimal results consistently. The initial phase involved laying out the comprehensive requirements essential for executing a full series of FMVSS 223 tests. Once the list of requirements was complete, the system's design took shape. Initial drawings were carefully created and subjected to review by expert test engineers. Subsequent feedback led to further refinements, with additional components incorporated to strengthen any areas of concern.

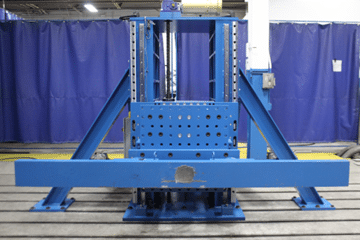

With the design phase accomplished, MGA’s team proceeded to machine and fabricate the components in-house. Subsequently, rigorous testing was conducted to ensure the precise operation of the system. Each cylinder's independent movement underwent manual examination to verify control and displacement. This careful approach played a critical role in tuning the cylinders for uniform extension and retraction rates, mitigating potential binding concerns. After a series of comprehensive checkouts and quality reviews, the new FMVSS 223 system was fully prepared for underride guard testing.

The final iteration of MGA’s new FMVSS 223 test system features a compression rating of 300,000 lbf, or 1,334,000 N. The system's design incorporates four rigid guides, strategically positioned to effectively eliminate any potential movement in the load form, maintaining stability both vertically and horizontally. To ensure a robust setup, two actuators have been fixtured within the frame. Furthermore, the test system also incorporates a mounting plate which effectively adapts the load form and load cells to the two actuators. The system comes standard with a 2,600 mm wide load form which provides ample coverage across the width of the two outermost supports on an underride guard. Moreover, the new test equipment can also seamlessly adapt to point-load load forms, making it compatible with P1 and P2 test locations as well. MGA has successfully utilized this system for more than a year and has seen outstanding results during testing while adhering to the NHTSA's latest FMVSS 223 specifications.

Here at MGA, we have proudly conducted FMVSS 223 testing for more than two decades, holding the NHTSA contract for the past 15 years. Leveraging our expertise, we are committed to making a positive impact on road safety on a daily basis. For more information on our FMVSS 223 testing services and equipment, please contact Jacob.Briskey@mgaresearch.com. We look forward to serving you and contributing to a safer driving environment.