Mon, Oct 28, 2019

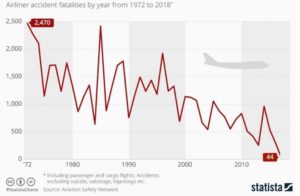

In the past 50 years, airplane manufacturers and regulators’ efforts in developing safer interiors have helped a steady decrease in airplane fatalities. Since the inception of the SAE AS8049 standard in the early 1990’s, MGA has supported the advancements of occupant safety in the aircraft industry. Our support, today, goes beyond the testing phase as we became active members of the SAE Aircraft Seating Committee and are constantly involved with the FAA training courses offered at the Civil Aerospace Medical Institute (CAMI). The committee sets forth recommendations for minimum structural and safety performances on aircraft interiors while CAMI ensures the industry is trained on recommended FAA practices. As the industry strives to make seats/interiors lighter and safer, our FAA accepted Sled testing facilities have been a dependable asset for those looking to receive high quality testing.

In the past 50 years, airplane manufacturers and regulators’ efforts in developing safer interiors have helped a steady decrease in airplane fatalities. Since the inception of the SAE AS8049 standard in the early 1990’s, MGA has supported the advancements of occupant safety in the aircraft industry. Our support, today, goes beyond the testing phase as we became active members of the SAE Aircraft Seating Committee and are constantly involved with the FAA training courses offered at the Civil Aerospace Medical Institute (CAMI). The committee sets forth recommendations for minimum structural and safety performances on aircraft interiors while CAMI ensures the industry is trained on recommended FAA practices. As the industry strives to make seats/interiors lighter and safer, our FAA accepted Sled testing facilities have been a dependable asset for those looking to receive high quality testing.

MGA counts 15 Pneumatic Accelerator Sleds companywide and 100+ dummies in inventory including EuroSID and THOR.

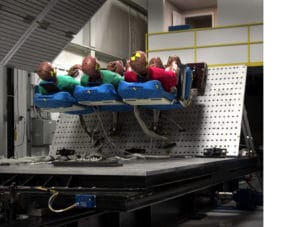

Our unique Pin-Pulse Style system has the capability to hit upwards of 100G’s acceleration and our ability to customize pins allows us to customize pulses with high repeatability. Our sled system utilizes a specialized 8’ x 12’ Aircraft carriage capable of reaching a 15˚ yaw in 2.5˚ increments (Image 2).

capability to hit upwards of 100G’s acceleration and our ability to customize pins allows us to customize pulses with high repeatability. Our sled system utilizes a specialized 8’ x 12’ Aircraft carriage capable of reaching a 15˚ yaw in 2.5˚ increments (Image 2).

The carriage’s exceptional size allows us to run single occupant seats, row-to-row quads, as well as installation tests. The carriage also has the ability to be pitched up to 60˚, accommodating vertical tests (Image 3). With recent uprgades to our sled system, such as new lighting and improved sled transfers, we are able to provide a faster service with industry leading video quality.

Combining our experience in the testing methodology and our involvement with the governing bodies that create the regulations, MGA offers its customers excellent testing services in a broad scope of work. Our testing facilities are A2LA accredited and capable of testing per AS8049-C, AC25.562-1B, and J211.

Our Scope of work includes:

- 14 CFR Part 23.562

- 15G and 19G Vertical, 21G and 26G Horizontal

- 14 CFR Part 25.562

- 14G Vertical and 16G Horizontal

- 14 CFR Part 27.562

- 30G Vertical and 18.4G Horizontal

- 14 CFR Part 29.562

- 30G Vertical and 18.4G Horizontal

In addition, examples of components tested in HIC, Structural – Pitch & Roll, and Head Path Trajectory include the following type of seats: first class, business, private, economy, crew, pilot, etc... Our Installation Testing includes bulkheads, lavatories, seat shells, cockpit instrumentation panels, galleys, and many other tests.

In addition, examples of components tested in HIC, Structural – Pitch & Roll, and Head Path Trajectory include the following type of seats: first class, business, private, economy, crew, pilot, etc... Our Installation Testing includes bulkheads, lavatories, seat shells, cockpit instrumentation panels, galleys, and many other tests.

MGA’s goal to provide customers with superior testing capabilities has enabled to be a reliable partner for the Aircraft Industry.